Dip Spin machines made to order

Effective method of coating bulk small parts

Dip Spin is the easiest and most efficient method of applying a wide variety of standard coatings to many bulk small parts. For example, the latest generation of high performance anti-corrosion coatings which can be applied in bulk by the dip spin process offer significant advantages over traditional electroplating without the disadvantages and complications of hazardous waste disposal, Hydrogen embrittlement or the use of pickling or plating solutions. Also, properties can be achieved which are not achievable by plating.

The process is so efficient that unit costs can be extremely low.

Principle of the operation

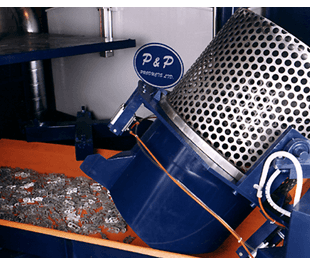

Small parts contained in a perforated basket are immersed in a liquid coating. After a short dipping time excess material is drained off and the basket is then centrifuged at a preset speed to 'throw off excess material which runs back into the dip tank for re-use. After a set time the basket is braked to a stop and then (if required) recentrifuged in the opposite direction. This process complete, the basket is braked again and unloaded. All the parts have now been given an all over even coating with no material wastage. The process is often repeated to build up film thickness and eliminate any touchmarks.

Special features

DS machines are operated by pneumatics (safer than electricity particularly in a solvent environment) and controlled by an air logic control system on the manual models or an electronic PLC on the automatic models.

Special high torque, low consumption air motors have been introduced on the new DS range slashing energy consumption by over 50%.

- Over 95% coating transfer efficiency means virtually no wastage

- Wide range of film builds possible

- Considerable time, labour and energy savings

- Safe and easy to operate

- Eliminates excess paint build, for example, in thread roots of male threaded components

- Auto weighing provides control of basket loads and automatic loading (automatic models only)

- Requires little floor space

- Quick and easy paint colour changes

Depending on the coatings used, we may advise that the machine or the unload section be housed in a booth to ensure good air movement over the entire operation.

The centrifuge baskets are robustly constructed and feature a dished base and perforated sides. A variety of mesh liners can be installed to enable coating of very small parts. Special purpose baskets can also be provided to improve distribution and eliminate dead spots as required.

The DS 250M is a small machine suitable for sample work or for small production batches possibly involving different colours or types of coating. It requires manual loading and unloading of the basket but still enjoys full automatic programmable control of the process parameters via an air logic control system. An electricity supply is not required to this machine.

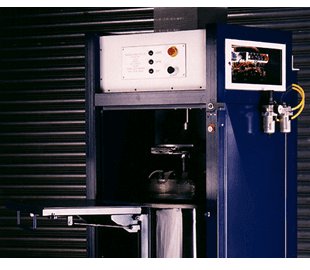

The DS 375A is basically a smaller version of the DS 450A (photographed). Both models feature full automatic handling as standard, however, customised variants can be produced as required. Both models are solidly constructed machines, designed for continuous production. They will coat large volumes of work easily, cheaply and reliably. Both models are supplied with our unique CPLS constant level container with continuous pumping and filtration of the paint for a quality finish and consistent performance throughout the working day.

The paint container can be easily drawn out (on runners provided) and the pump system re-connected for continuous circulation whilst not in use. This facilitates easy colour changes and reduces settling out of the solids in the paint.

Control panel

- PLC data access panel enabling restricted access to timers for dip, spin forward, brake and spin reverse

- Rev counter

- Forward and reverse speed controls

- Status indicator lamps

- Emergency stop

- Auto weighing control

- Auto/manual switch

- Full manual controls

Basic specifications

| DS 250M | DS 375A | DS 450A | |

| Maximum Basket Load | 10 kg | 40 kg | 70 kg |

| Basket Volume (usable) | 310.24 fta | 1.02 ft3 | 1.77 ft7 |

| Basket Diameter | 250mm | 375mm | 450mm |

| Basket Depth | 200mm | 375mm | 450mm |

| Air Consumption | 10cfm | 12cfm | 12cfm |

| Machine Footprint | 520mm x 520mm | 1620mm x 1500mm | 1950mm x 1800mm |

- Nominal figure 70% of actual volume

- Excluding CPLS system

Typical cycle time (immediately repeatable with dual transfer system) would be approximately two minutes. The DS 450A can, therefore, coat up to 21 00kg of components per hour.

P&P Products Ltd persue a policy of continuous product development, therefore, product details and specification may differ from those appearing here

Examples of coatings which can be used with the DS machines include:

- Deltaseal

- Deltatone

- Dacromet

- Zinc Rich

- Oils/Lubricants

- Xylan

- Teflons

- Lacquers

- Waxes

- Flouropolymers

- Phenolics

- Polyseal

- Dry Bonded Lubricants

- Stains

- Organic and Inorganic Coatings

- Alkyd Based Primers/Finishers

- Acrylics

- Matt Resin Coatings

- Molykote OPTIONAL EQUIPMENT

- Vibratory feeder or load conveyor

- Off load conveyor

- Oven (batch or conveyor type)

- Custom load chutes

- Canting head/Tumbling cycle (for additional re orientation of difficult parts)

Talk to us about your design and manufacturing requirements.

Call us on

01274 296 793

or

01274 918 737